- Home

- OFweek News

- Interview with Euroklimat: How Advanced Dehumidification Technology is Revolutionizing China's $100B Lithium Battery Industry

Interview with Euroklimat: How Advanced Dehumidification Technology is Revolutionizing China's $100B Lithium Battery Industry

Published: May 22, 2025 15:31

With only five years remaining to achieve China's carbon peak and carbon neutrality goals, the nation's industrial green transformation has entered critical waters. On April 28, 2025, the Ministry of Industry and Information Technology officially launched its annual energy-saving and carbon reduction technology and equipment promotion initiative, requiring key industries to accelerate the adoption of energy-efficient technologies. The ambitious target: cultivate 100 major low-carbon technologies by 2025, driving trillions in green investment.

High energy-consuming lithium battery companies are taking decisive action. Currently, the global lithium battery industry has established over 20 carbon-neutral certified factories, with China accounting for more than 70% of these facilities. CATL's Guizhou facility, Gotion High-Tech's Jinzhai plant, Tianneng's Guizhou factory, Chengdu B&M Science Technology's cathode material facility, and Dangsheng Shudao's manufacturing plant have emerged as representative zero-carbon factories.

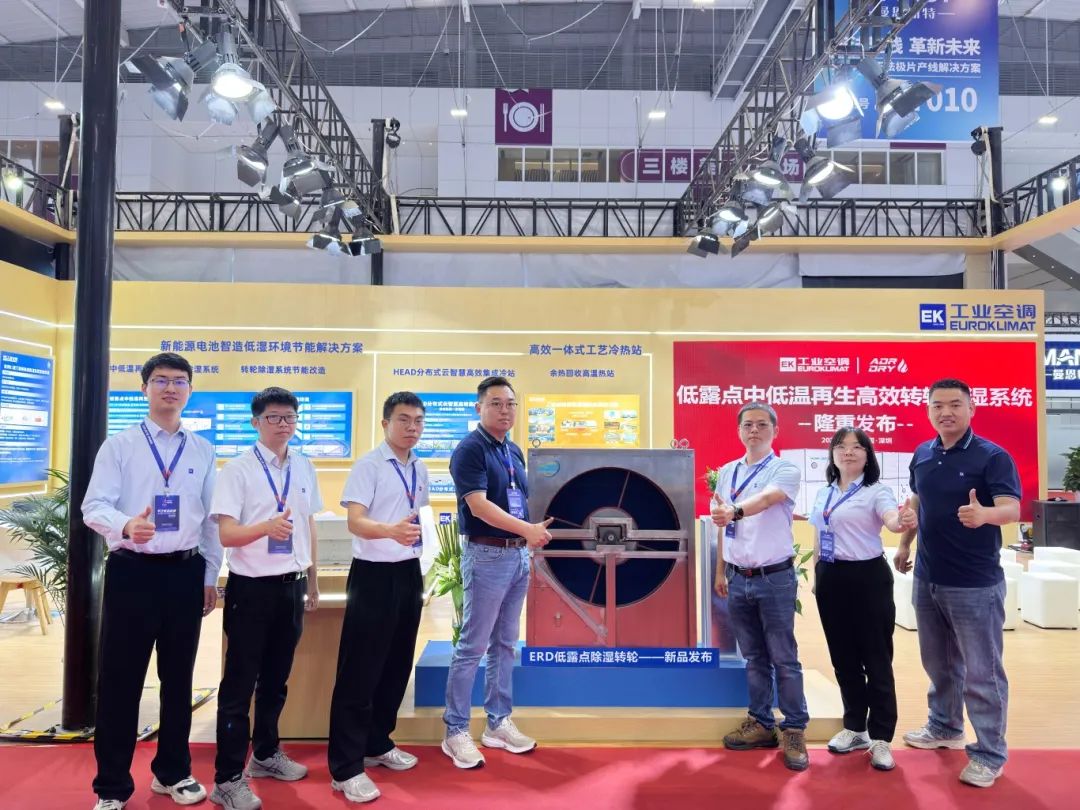

Lithium battery energy-saving equipment is making its mark. At the globally watched CIBF 2025 from May 15-17, Euroklimat Air Conditioning established a dedicated "Energy-Saving Retrofit Projects" zone, launching breakthrough products including the ERD low dew point dehumidification rotor and ADR-DRY low dew point medium-low temperature regenerative high-efficiency rotor dehumidification system. Through demonstrated energy-saving retrofit projects, EK showcased pathways for new energy battery consumption reduction, helping enterprises transform energy costs into core competitive advantages.

source: Euroklimat

During the exhibition, OFweek’s Editor of Lithium Battery Network engaged in discussions with Mr. Cai Xiaohui, Senior Industry Manager at Euroklimat, dissecting Euroklimat's energy-saving technology core and business logic.

source: OFweek Energy

01 Decoding Key Lithium Battery Energy-Saving Solutions

At this CIBF exhibition, EK unveiled its independently developed ERD low dew point dehumidification rotor, featuring six major technical advantages:

· All-imported material rotor core with dehumidification performance meeting national advanced standards

· High-density rotor materials with superior strength and excellent sealing

· Organic content below 2%, high temperature resistant

· Active components exceeding 80%, strong moisture absorption

· HF hydrofluoric acid corrosion resistant, extended service life

· Non-toxic, non-flammable rotor materials that are water-washable

Leveraging the powerful advantages of the ERD low dew point dehumidification rotor, EK's integrated rotor dehumidification station achieves supply air dew points of -80°C, compressing dew point compliance time to under one hour. This enables rapid, precise humidity control at extremely low levels, meeting the stringent low dew point environmental requirements across all lithium battery production stages.

Simultaneously, the full-lifecycle high-efficiency integrated rotor dehumidification station features integrated intelligent adaptive control, combined with the EK-AIoT energy management platform's automatic optimization capabilities. The system automatically adjusts operating parameters based on real-time production environment changes, ensuring humidity remains consistently within set parameters, significantly improving control precision and stability.

The ADR-DRY low dew point medium-low temperature regenerative high-efficiency rotor dehumidification system achieves 50°C-90°C medium-low temperature regeneration without increasing rotor area. Compatible with cloud-intelligent high-efficiency integrated cooling stations and waste heat recovery heat pumps, it delivers supply air dew points as low as -60°C with system energy savings exceeding 30%, addressing the persistent challenges of high energy consumption and elevated production operating costs for new energy battery enterprises, supporting low-carbon production for new energy companies.

Cai Xiaohui shared that for a new energy battery production line project in Jiangsu Province, EK selected one dehumidifier for energy-saving design during equipment supply. After system commissioning and operation, the system achieved cost savings exceeding 20%, earning client approval. EK has since screened and designed energy-saving solutions for the project's remaining dehumidification equipment, ultimately selecting nearly 20 units for energy-saving retrofits, currently in the supply and delivery phase.

02 Technology Iteration and Ecosystem Collaboration

EK has successfully applied cloud intelligence to practical implementation. For instance, the distributed cloud-intelligent high-efficiency integrated cooling station has constructed an optimal energy efficiency solution:

1. Full Variable Frequency Coordinated Control: The cooling station integrates full variable frequency compressors, water pumps, and cooling tower fans. Through an adaptive intelligent integrated control system, equipment frequency is dynamically adjusted in real-time based on load, ambient temperature, and water temperature, reducing ineffective energy consumption and improving system efficiency by over 30% compared to traditional solutions.

2. AIoT Cloud Platform Empowerment: The cooling station is equipped with the EK-AIoT cloud platform, capable of real-time data collection including chilled/cooling water inlet and outlet temperatures, pressure differentials, and equipment operating status. AI algorithms construct system efficiency models to optimize operating strategies. The platform supports digital twin technology, enabling virtual equipment mapping for fault simulation and predictive maintenance.

3. Multi-dimensional Intelligent Management: The platform provides comprehensive equipment lifecycle management, including energy efficiency analysis, abnormal alerts, automatic maintenance work order dispatch, and continuous control logic optimization through machine learning, ensuring systems consistently operate within high-efficiency zones.

According to Cai Xiaohui, EK's HEAD cooling station possesses comprehensive industrial internet capabilities, "with hardware layers standard-equipped with RS485 interfaces and Modbus RTU protocols, enabling integration with third-party industrial internet platforms for bidirectional data interaction, helping users build intelligent manufacturing ecosystems."

This case study not only validates technology reliability but also provides the industry with replicable energy-saving retrofit templates.

source: Euroklimat

03 Waste Heat Recovery Drives Cost Reduction Exceeding 50%

A notable phenomenon in lithium battery production is that coating, drying, formation, and air compressor cooling processes generate substantial waste heat at 40°C-70°C, which traditional methods discharge directly, causing energy waste.

At this exhibition, Euroklimat Air Conditioning showcased waste heat recovery high-temperature heat stations addressing this pain point: Euroklimat high-temperature heat stations prioritize recovery of stable waste heat sources such as air compressor cooling water and high-temperature drying exhaust, producing 80°C-120°C high-temperature hot water/steam to directly replace boiler heating.

Cai Xiaohui illustrated that when EK waste heat recovery high-temperature heat stations utilize 30°C waste heat sources to produce 80°C hot water, heat pump unit energy efficiency ratios reach approximately 3.3. Compared to gas boilers, operating costs can be reduced by over 50%, with investment payback periods of only 1.5-3 years (based on gas prices of 3.5 yuan/Nm³/h and electricity prices of 0.56 yuan/kWh).

04 Conclusion

Zero-carbon factories represent not merely technological upgrades, but the starting point for manufacturing value reconstruction. With the EU Carbon Border Adjustment Mechanism (CBAM) fully implementing in 2026, China's lithium battery industry urgently needs to transform carbon emission constraints into international competitive advantages through technological innovation and model transformation.

In this green revolution, the deep participation of equipment suppliers like Euroklimat Air Conditioning is pioneering an innovative path that balances efficiency with sustainability for the industry.