U.S. Tariff Policy Takes Effect, Sending Shockwaves Through Global Auto Industry

Published: April 09, 2025 14:30

source: 汽车公社

The article is originated from 汽车公社

Introduction

The implementation of stringent tariff policies marks the beginning of a new chapter for the global automotive industry.

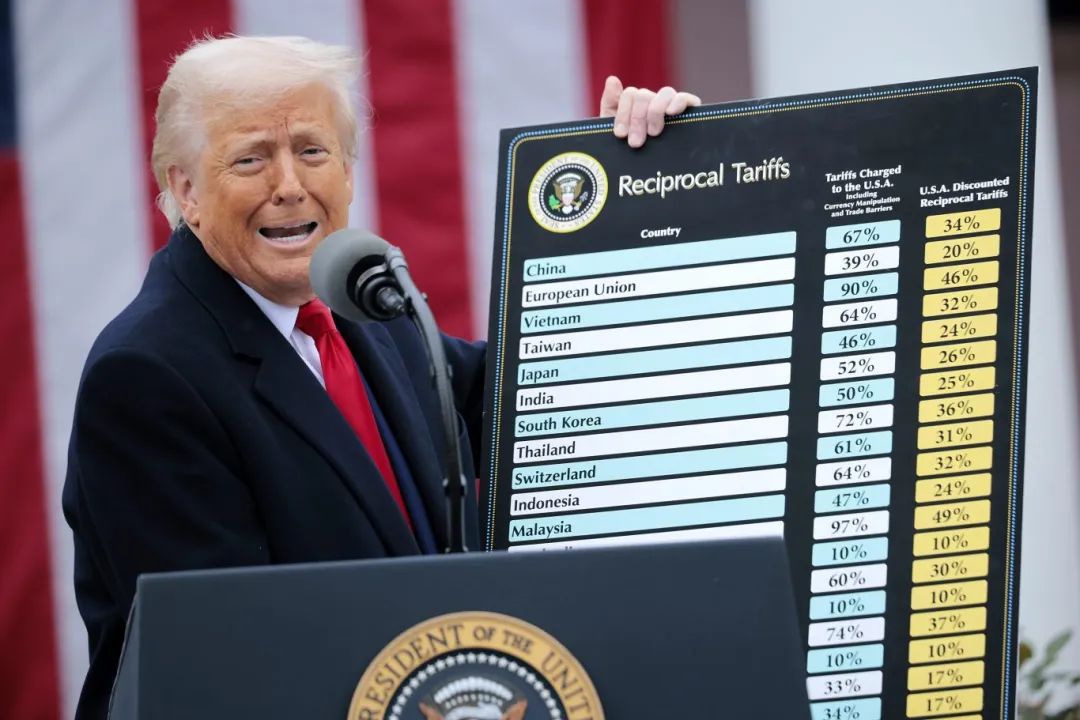

April 2nd will be forever etched into the history of the global automotive industry. President Trump officially launched his plan to impose comprehensive tariffs on various U.S. trading partners, ranging from a minimum reciprocal tariff of 10% to as high as 49%, though automobiles are not part of the reciprocal tariff program.

Although the U.S. had announced a week earlier that it would impose a 25% tariff on all imported vehicles and critical components, the more detailed country-specific tariff policies revealed a week later detonated like a bombshell, sending shockwaves throughout the global automotive industry and international trade.

According to charts displayed at the news conference, tariffs range from 10% on British goods to 49% on Cambodian products. Chinese products will face a 34% tariff, South Korean goods 25%, European Union exports 20%, and Japanese goods 24%.

Without question, this announcement—which Trump called "Liberation Day"—represents another escalation in America's expanding trade policies designed to protect U.S. industries by erecting barriers to foreign competition.

source:汽车公社

As the most significant component of U.S. global trade, automobile and related parts tariffs are a critical concern for all countries. Previously, the U.S. imposed only a 2.5% tariff on imported vehicles; under Trump's tariff policies, this tax has increased nearly tenfold.

Trump previously stated explicitly that vehicles manufactured in the United States would be exempt from tariffs. This mechanism aims to drive the automotive supply chain back to American soil but introduces new variables into the complexities of cross-border trade and supply networks.

The U.S. has long been a vital participant in the global automotive market. In 2024, its imported vehicle volume reached 8 million units, accounting for 50% of domestic auto sales, with a total trade value of $474 billion including parts—representing 28% of global automotive trade. This enormous share means that any fluctuation in the U.S. automotive market can create ripple effects throughout the global industry, leaving automotive sectors that depend heavily on the American market in unprecedented difficulty.

Increased production costs, market share losses for multinational automakers, profit declines, consumer hesitation, and rising vehicle prices... as these rigid tariff policies take effect, a new round of restructuring in the global automotive industry landscape is underway.

01: Stock Prices Plummet, Multinational Automakers Suffer Heavy Blows

Trump's tariff announcement a week ago had already sent shockwaves through the automotive industry, with capital markets reacting violently and automotive stocks becoming the hardest hit.

Although seemingly beneficial for domestic U.S. manufacturers, General Motors' stock plunged more than 7% and Ford fell over 4% within the context of a globally integrated industry. On one hand, increased costs for imported components will directly drive up production expenses; on the other hand, shifts in the U.S. market competitive landscape force them to face pressure from both domestic and international rivals.

In Europe, a key birthplace of the global automotive industry, stocks of Porsche, Mercedes, BMW, and Volkswagen all dropped by more than 5%. For Japanese and Korean automakers who are even more dependent on the U.S. market, the situation is dire: Toyota's stock fell 9.4%, Nissan dropped 9.3%, and Hyundai plummeted 11.2%.

source:汽车公社

Clearly, these precipitous stock declines for companies with significant positions in the global automotive industry reflect not only investor concerns about their future performance in the U.S. market but also severely impact confidence in the entire European, Japanese, and Korean automotive sectors. The policy has made the prospects for overseas automakers in the American market increasingly uncertain, forcing them to recalibrate their market development strategies.

Take the European Union as an example: its automotive exports to the U.S. amount to €38.4 billion, representing 19% of total automotive exports. German brands like BMW and Volkswagen depend on the U.S. market for approximately 13% of their production, while luxury brands like Mercedes and Porsche derive nearly 30% of their revenue from America. This means the U.S. market is crucial for the German automotive industry—once the American market comes under pressure, German automakers will suffer severely.

According to the German Association of the Automotive Industry, after tariff implementation, the per-vehicle cost for these products is expected to increase by $12,000-$23,000. The European Association of Automotive Suppliers has also warned that the transatlantic supply chain involves thousands of companies, and tariffs will obstruct component flow, ultimately pushing up final prices by 15-20%. This is because German vehicle production heavily relies on global supply chains, with many critical components imported from around the world, and tariff increases will substantially raise import costs for these components.

In fact, facing Trump's tariff policies, overseas automakers have already taken action to mitigate potential impacts on their businesses and operations. As a European company that has operated in the U.S. for over 25 years, Mercedes-Benz executives stated days ago that they've accelerated inventory stockpiling in the U.S. before tariffs take effect to avoid paying high premiums on foreign-manufactured vehicles and parts for as long as possible.

source:汽车公社

Reports suggest Mercedes may relocate production of its GLC SUV to the United States. Of the more than 300,000 vehicles Mercedes sold to U.S. dealers last year, approximately two-thirds were imports, including U.S.-assembled GLE and GLS models that still use engines and transmissions from Europe.

Mercedes-Benz estimates that the 25% tariff will impact its total profit by about 2.5 percentage points. According to brokerage forecasts, the tariff policy could cost Mercedes-Benz approximately $1.7 billion, representing 14% of expected operating profit.

Mercedes-Benz is also concerned that only about 30-40% of vehicles manufactured in the U.S. are sold domestically, with the rest exported to global markets outside America. Therefore, these products could face retaliatory tariffs from other importing regions worldwide.

Additionally, following tariff implementation and subsequent price increases, reports suggest Mercedes may consider discontinuing sales of more entry-level vehicles in the U.S., as tariff policies could make these lower-priced vehicles unprofitable. This forces Mercedes-Benz to sacrifice sales volume and focus exclusively on high-end models in the American market.

The German Association of the Automotive Industry further predicts that tariffs could reduce European automakers' U.S. market share by 8-12 percentage points. This prediction is well-founded—as tariffs are implemented, European vehicles will gradually lose their price advantage in the American market, and consumers purchasing vehicles will increasingly favor more affordable domestic brands or other imported brands.

02: Chain Reaction Leading to Potential Market Collapse

The predicament of Japanese and Korean companies, known for their economic efficiency, may be even more severe than that of European automakers like Mercedes. AFS predicts that tariffs could reduce Japanese and Korean automakers' U.S. sales by 40-60%, with gross margins compressed to below 5%—undoubtedly a massive blow for Japanese and Korean automakers operating on high-volume, low-profit models. The impact on Japanese automakers is particularly significant; according to customs data, automobiles are Japan's largest export to the United States, accounting for 28.3% of Japan's total exports to America in 2024. Consulting firms believe Toyota may face the greatest impact due to its enormous U.S. sales volume, where it has consistently ranked among market leaders.

Data shows that among the top eight automakers by sales in the U.S. for 2024, Asian brands occupy six positions. Toyota leads with 1.98 million vehicles sold annually, surpassing American automotive giants Ford and General Motors' Chevrolet. Honda and Nissan rank fourth and fifth, followed closely by Hyundai and Kia, with Subaru ranking eighth.

source:汽车公社

According to corporate financial reports, most of these Asian automakers derive the majority of their revenue from North America, meaning any tariff impact is unlikely to be easily offset. In 2024, South Korea and Japan exported 1.4 million and 1.3 million vehicles to the United States, ranking second and third among countries exporting cars to America.

Although giants like Toyota and Nissan have large production facilities in the U.S., their expansion capacity is far from sufficient to offset tariff impacts. Even if automakers wish to shift production to the United States to avoid tariffs, factory relocation cannot be completed "overnight" and requires billions of dollars in investment.

While the impact on EU, Japanese, and Korean automakers affects sales volumes, profits, and market share—with potential backstops from other global markets—the situation is far more dire for Canada and Mexico, which focus on supply chains and manufacturing.

As U.S. neighbors, Canada and Mexico have close automotive industry cooperation with the United States, collectively building the North American automotive supply chain. In 2024, all 10.2 million vehicles produced in U.S. factories used large quantities of imported parts, primarily from Canada and Mexico. In 2024, 86% of Canada's 1.3 million produced vehicles were sold to the United States, while 61% of Mexico's 4 million vehicles were exported to America.

source:汽车公社

However, Trump's tariff policy threatens to "sever" this supply chain.

According to Mexico's "El Economista," Mexican auto parts exports to the U.S. account for 42.8% of total American imports, and tariffs will cause Mexico's automotive industry to lose $12 billion annually. Increased tariffs significantly raise costs for Mexican auto parts companies, reducing orders. Some companies are even considering relocating production bases to other countries to lower costs and avoid tariff risks.

Canada's automotive industry faces similar challenges. Many Canadian auto parts companies supply American automakers, and tariff increases reduce these companies' competitiveness in the U.S. market, leading to decreased orders. Since Canada's automotive industry is primarily concentrated in Ontario, the region's economy will be severely affected, with many workers potentially facing unemployment.

03: Trade War Escalation Shakes Global Automotive Landscape

Trump's automotive tariff policy has undoubtedly disrupted the existing supply chain balance. After tariff implementation, key component costs are expected to rise sharply by 35-50%. Data from the Peterson Institute for International Economics shows this will increase per-vehicle costs for domestic U.S. automakers by $3,500-$12,000.

Swamy Kotagiri, CEO of Canadian auto supplier Magna, stated there are no simple methods to help automakers absorb the additional costs from tariffs, and most of these costs will ultimately be passed on to consumers.

Some institutions predict this tariff storm may not only replay the history of car prices soaring 20% during the pandemic but also trigger a triple transmission mechanism through "new car prices - parts costs - insurance expenses." New car prices will jump first, followed by original equipment parts, and finally insurance companies will have to transfer claim costs to consumers. Currently, auto insurance premiums are already 60% higher than pre-pandemic levels, and a new round of price increases could push this figure even higher.

source:汽车公社

Consumers planning to purchase new vehicles may delay or cancel their plans due to price increases. This will directly reduce automotive market demand, turning a 1% annual increase into a 3% decline. The significant boost in March retail and overall industry sales in the U.S. market might be attributed to panic buying by American consumers who fear threats to new car prices and availability.

Experts widely predict that as prices rise, purchasing will slow, forcing auto brands to seek opportunities to protect profits elsewhere, potentially targeting marketing and advertising budgets.

The U.S. Automobile Dealers Association points out that tariffs will cause 8 million households to postpone vehicle purchases—representing a massive consumer group. Their delayed purchasing plans will not only affect the automotive industry's sales performance but also negatively impact the broader consumer market.

As an important component of the consumer market, declining automotive demand could suppress production and sales in related industries, affecting overall economic growth. According to Standard & Poor's, U.S. annual total vehicle sales may drop to 14.5-15 million units in coming years.

Against the backdrop of booming global new energy vehicle development, the U.S. is actively promoting transition to new energy vehicles. However, Trump's tariff policy creates enormous obstacles for America's new energy vehicle industry development. Bloomberg analysis indicates that U.S. automakers may be forced to reduce R&D investment in electrification to lower costs. Reduced R&D investment will directly impact technological innovation and product upgrades in America's new energy vehicle industry, putting it at a disadvantage in global competition.

For European, Japanese, and Korean automakers, U.S. tariff policies inevitably force them to reconsider the importance of China as an enormous global automotive market. With limited growth in Europe and America facing difficult times, the Chinese market will become the best haven for global multinational automakers. This requires multinationals to value Chinese technology and supply chain systems while seeking better development and growth paths.

source:汽车公社

For China, despite exporting few vehicles to the United States, the gradually globalizing Chinese automotive industry may also face significant challenges.

BYD, as a global leader in new energy vehicles, has consistently focused on global market expansion. Its original plan to invest in factory construction in Mexico aimed to leverage Mexico's geographical position and resource advantages to further expand its North American market share. However, the introduction of tariff policies creates many uncertainties for BYD's plans.

CATL, as the world's largest power battery supplier, also plans to invest in battery factory construction in Mexico to supply Tesla, Ford, and other companies. But tariff implementation may affect CATL's investment decisions and supply chain arrangements.

Looking long-term, as global trade moves toward decoupling, Chinese automakers expanding overseas must accelerate localization to reduce tariff risks. This means companies need to establish more comprehensive production systems and supply chain networks in target markets, achieving localization in raw material procurement, manufacturing, sales services, and other links.

Trump's automotive tariff policy resembles a massive stone thrown into a lake, with ripples reshaping the global automotive industry landscape. In the short term, all participants lose; but from a long-term perspective, this crisis may accelerate supply chain localization, technological independence, and regional economic integration. For China, how to consolidate manufacturing advantages and strengthen technological barriers during this storm will be key to determining industrial discourse power for the next decade.